Sounds a bit complicated above but when you have the overdrive unit off you will easily see what i mean.Took me about 3 attempts till it dropped fully into position.

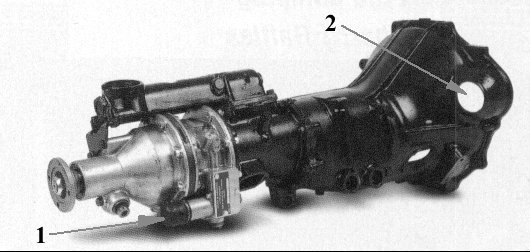

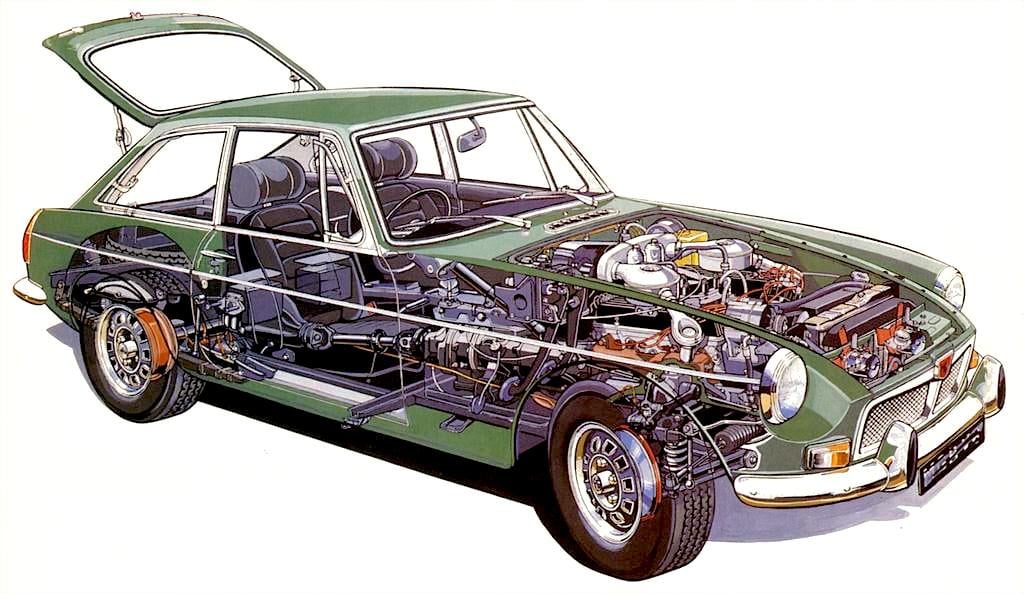

Rotate the flange again slowly ANTICLOCKWISE and it should drop again into position then remove the cord holding back the cam follower. Slowly rotate the prop drive flange ANTICLOCKWISE and the unit will drop further as the splines mate up. At the flip of a switch, the overdrive unit gives a reduction in gear ratio, basically adding a gear. The overdrive is basically an electromagnetic, solenoid-activated planetary gear set that sits between the normal manual transmission and the driveshaft. Lock the main shaft from the gearbox so it will not rotate in a position that the lowest part of the cam collar is where the pump follower meets. In the 1940s he adapted this idea of epicyclic gears for an overdrive unit.Fit a cord around the pump cam follower to hold it in to enable it to drop over the cam collar whilst refitting the unit.Afterwards do not turn the prop drive flange whilst handling or the splines will misalign. The lower set inside the unit will rotate – i found the head of a spanner fitted well into the splines to turn. When refitting make sure the splines inside the unit are aligned before lowering it onto the gearbox.If it falls out it will drop down into the gear box!! Same when refitting wrap and pack some rags around the base of the shaft in case the ball bearing drops out. Be careful when you remove it as there is a small ball bearing mounted in the shaft. There is a cam collar mounted on the main shaft to drive the overdrive unit pump.It is a right swine to refit if you don’t know the trick. The Haynes manual simply says to refit as removal which is absolutely useless.

0 kommentar(er)

0 kommentar(er)